RSA - GLOBAL CONTROLS

Trusted experts in end-to-end motion and control automation solutions for manufacturing.

Since 1966, RSA has been a trusted partner in delivering complete automation solutions to manufacturers. Serving industries such as automotive, food processing, packaging, and industrial manufacturing, RSA specializes in providing comprehensive product selection, system design and integration, and after-sales support to help businesses enhance productivity and reduce downtime.

With a dedicated team of sales professionals and engineers, RSA ensures that each customer receives the best products for their automation needs, along with personalized service and expert advice to optimize operations. Global Controls has been a systems integrator since 2000, supporting automation and motion control projects.

In December 2021, Motion & Control Enterprises (MCE) acquired RSA Solutions and Global Controls, now collectively known as RSA Solutions. Based near Chicago, RSA is a leader in MCE’s Automation category and their experienced teams serve customers across Illinois, Indiana, and Wisconsin.

THE RIGHT SOLUTIONS FOR AUTOMATION….EVERY TIME.

PRODUCTS & SOLUTIONS

RSA’s product offerings from leading manufacturers like Lenze, Parker, MTS, Schneider Electric, Epson and more, cover a wide range of automation needs, from motion control and vision systems to custom programming solutions. Our team of trained sales experts collaborates with clients to identify the most effective solutions for each application, guaranteeing both cost-effectiveness and ease of use.

MOTION & MACHINE CONTROL

RSA offers a wide range of high-quality AC/DC drives, HMI/MMI, Motors, Multi-Axis Controllers, Motion Controllers and Position Feedback Encoders.

In addition to product selection, RSA excels in system design and integration, such as single and multi-axes systems using AC, DC, Stepping, and Servo motor technologies. We offer end-to-end services that include designing, building, programming, and installing custom automation solutions that meet the unique requirements of our clients.

POSITIONING & POWER TRANSMISSION

RSA provides a comprehensive selection of position and power transmission products solutions. From the working end of the process to the final control of the motion and machine control, our mechanical engineers will help you to specify the correct mechanical and power transmission products to complete your application.

ROBOTICS

Whether designing a new line, or dealing with problems on a current line, our engineers can help you create a robotics solution for your application. We have a wide assortment of articulated arm robots and cobots for high-speed assembly, material handling, diecast, dispensing, material removal, material cutting/trimming, picking and packing operations. We can also analyze and select the best robot for your application, including machine vision cameras for robot guidance. Let us help you with palletizing, case packing, metal press loading, bulk handling, vision inspection, press loading and unloading, circuit board inspection, scoop insertion, and more.

VISION, CODE READING AND LIGHTING

Bring vision assisted production to your plant floor today with RSA’s engineering team and vision specialists. We are experts in the design and integration of in-process vision systems for measurement, inspection, gauging, identification, and sortation of product. We specify the best vision or code reading product to fit your application requirements and ensure your application is vetted and will work in your production environment.

SENSING

Bring vision assisted production to your plant floor today with RSA’s engineering team and vision specialists. We are experts in the design and integration of in-process vision systems for measurement, inspection, gauging, identification, and sortation of product. We specify the best vision or code reading product to fit your application requirements and ensure your application is vetted and will work in your production environment.

SAFETY

RSA offers the world's largest range of safety switchgear and systems for the protection of your most valuable assets. Ensure the safety of your employees and machinery with safety light barriers, food industry light curtains, safety switches and monitoring, programmable safety controllers, machine guarding and more.

CONNECTIVITY

RSA’s networking solutions enable machines, devices and systems to communicate. Our engineering and technology support team will help you to identify and program the technologies for in-plant and remote connectivity, providing access to programmable logic controllers (PLCs), motion controls, drives, and other supporting hardware.

Value-Added Services & Solutions

RSA targets several key industries, including:

Automotive: Providing automation solutions that enhance manufacturing processes, streamline production, and reduce downtime in automotive production lines.

Food Processing: Offering systems that optimize food production and packaging while ensuring safety and compliance with industry standards.

Pharmaceutical: Delivering automation systems for the pharmaceutical industry to ensure precise control, regulatory compliance, and efficient production processes in drug manufacturing.

Packaging: Supplying automation solutions for packaging systems, improving efficiency, accuracy, and speed in packaging lines.

Industrial Manufacturing: Supporting a wide range of manufacturing applications with tailored automation solutions that help improve operational efficiency and reduce costs.

RSA offers a comprehensive range of services and expertise in automation solutions, specializing in:

PRODUCT SELECTION

RSA's trained sales team assists customers in selecting the best products for their specific automation needs. They provide expertise in motion control, vision systems, and programming, ensuring cost-effective solutions that are easy to use and tailored to the application.

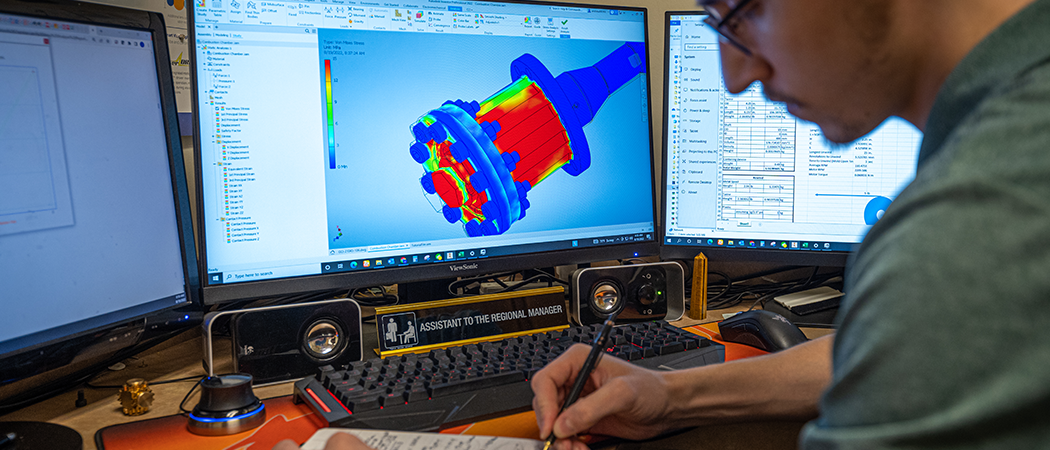

SYSTEM DESIGN AND INSTEGRATION

RSA's engineering team designs, builds, programs, and installs custom automation systems. They provide end-to-end services, handling every step of the process from initial design to final installation, ensuring that systems meet the unique needs of the client.

AFTER-SALES SUPPORT

RSA offers training opportunities for customer teams, ensuring they are well-equipped to operate and maintain the automation systems. This ongoing support helps clients maximize the value of their investment by ensuring smooth system operations long after installation.

These offerings are complemented with expertise in automation solutions, providing high-quality products and services that help customers optimize operations, improve quality and reduce downtime. Our focus on comprehensive support and tailored solutions is a key factor in delivering long-term value to clients.

REDUCING COSTS WITH KITTED SYSTEMS

RSA helped a manufacturer of sheeter machines transition to completely kitted systems, delivering fully assembled electrical panels ready for installation. This solution, which included servo motors, VFDs, and HMI/PLC systems, allowed the manufacturer to reduce costs for an order of 60 machines in 2024. By providing in-house software upgrades and control narratives, RSA significantly lowered machine costs while improving operational efficiency. The result was substantial savings and enhanced productivity for the manufacturer.

Need a customized solution for your operation?

Learn how MCE can help

Brands & Manufacturers

BEST-IN-CLASS SUPPLIERS

We proudly partner with industry-leading manufacturers to offer products that meet the highest quality and performance standards. Our trusted brands include Lenze, Parker, ABB, Epson, Yaskawa, Delta NSK, Nabtesco, Nidec, Teledyne Dalsa, Schmersal, Tri-Tronics, EWON, Red Lion, and much more.

RSA Solutions for Automation

Corporate Office & Regional Fulfillment Center

RSA Solutions for Automation

8:00 AM to 5 PMX

1055 Remington Blvd., Suite A

Bolingbrook, IL 60490

(630) 377-5385

info@rsainfo.com

Global Controls

Contact us

NEED A QUOTE, WANT TO SCHEDULE SERVICE, OR JUST NEED SOME EXPERT HELP?

Connect with us today through the form below.

In Case You Missed It

.png)