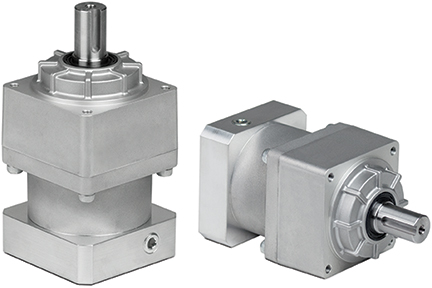

VRSF Series

The intelligent, value engineered selection for lower duty cycle servo and stepper motor applications. The VRSF utilizes a lightweight aluminum frame, making it optimal for traveling axes and end of arm tooling systems. Helical cut gearing allows the VRSF to operate much quieter than the industry standard economy products which rely on spur gearing. The VRSF comes standard with 15 arc-minutes of backlash, but can also be configured to higher accuracy levels.

The VRSF is available in four frame sizes, putting out a peak output torque of 274Nm across 9 reduction ratios. The VRSF is the ideal choice for OEMs producing high volume machines where cost is critical, accuracy relatively important and duty cycle not overly extreme. The VRSF’s aluminum body has made it a popular choice in medical, food packaging and other harsh environments. The VRSF can be fitted with a NEMA output flange, for standardized connection to customer equipment.

Product Features

- Carburized helical gears with proprietary secondary finishing process for higher accuracy and smooth, quiet operation

- One piece output shaft and planet carrier with two bearings straddling the planet gears. Higher stiffness and safety factor, with guaranteed alignment of gearing

- Aluminum body for a light weight solution, capable of withstanding corrosive environments

- Input seal allows for IP65 ingress protection

- Optimized mounting system with active centering on motor pilot diameter guarantees alignment of motor. Motor can be installed in any orientation

- True concentric clamping connection, optimized for your motor. Reduced inertia for dynamic performance and balanced for high speed operation