Originally posted by Parker Electromechanical Team on October, 2016

It’s well documented that creating compressed air for use by pneumatic cylinders is not a particularly cost-effective process, largely as a result of generator and system inefficiencies. With accounts departments leaning hard on engineers to deliver lower operating costs, increasing numbers are turning to the latest electric actuator solutions.

It’s well documented that creating compressed air for use by pneumatic cylinders is not a particularly cost-effective process, largely as a result of generator and system inefficiencies. With accounts departments leaning hard on engineers to deliver lower operating costs, increasing numbers are turning to the latest electric actuator solutions.

Why so?

Well, the design features of electric actuators mean they are able to deliver enhanced performance levels while also achieving lower total energy consumption. In fact, based on trials, savings of $4,000 can be anticipated for a typical single-actuator application over a two-year period.

Two steps become one

In pneumatic systems, two steps are necessary to produce compressed air: electricity first produces air, before air pressure is converted into linear movement using a pneumatic cylinder. Similarly, two stages are required in a traditional electric solution, namely converting motor rotation to the movement of the electric actuator.

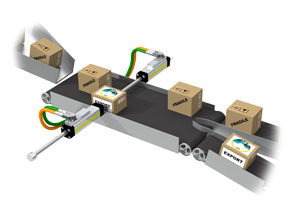

However, this double step can be reduced, with subsequent energy savings, by using a linear motor rod-style actuator solution such as an ETT series unit, which is able to directly generate linear motion through the principle of electro-magnetism.

However, this double step can be reduced, with subsequent energy savings, by using a linear motor rod-style actuator solution such as an ETT series unit, which is able to directly generate linear motion through the principle of electro-magnetism.

Another favorable attribute of a linear motor actuator compared with a pneumatic solution is the precise positioning achievable along its entire stroke. On-board feedback via an integrated analogue position sensor allows positioning precision to within 0.05mm.

Significant savings potential

The technical advantages of the latest electric linear motor actuators are clear, but what about the cost comparison we hear you ask?

Well, consider a typical application involving the transfer of a 15kg load at 30 cycles per minute, for example. Here, a pneumatic solution would work with a pressure of approximately 2 bar, while the ETT solution consumes just 30W of electricity every cycle. Sure, the initial start-up cost for the electric actuator solution is higher than its pneumatic counterpart, but the cumulative energy cost savings mean your initial investment would be recouped well within one year.

Moreover, just 24 months after start-up, savings will have increased to around $4,000. This savings is for just one actuator—if you multiply the number of actuators found on a typical production line it’s easy to see the vast savings possible.

Learn more

Article contributed by Alessandro Porro, product manager, Motors, Electromechanical Division Europe, Parker Hannifin Corporation.