By Travis Schneider, Product Manager – Automation Group • Parker Hannifin

When commercial electromechanical actuators or stages first became available, a new machine’s design was often dictated by the limited number of products available to designers with very rigid designs that did not allow for customization. More than four decades later, however, the “one size fits all” approach to machine design is far less common. Because your customers are demanding highly configurable and adaptable machines, machine designers are expecting their automation suppliers to deliver components that allow them to produce a new generation of more flexible machines.

Modern machine designers are rightfully afraid of painting themselves into corners. Throughout the design phase of a project, a good machine designer is constantly trying to manage the potential variations or risk of variation. Selecting a flexible product that allows for slight variations without forcing major design changes saves both time and effort. So what are some of these aspects to consider when gauging a product’s flexibility?

Stroke Capacity

Does the actuator under consideration accommodate a variety of stroke lengths as standard? Does a variation in stroke length affect performance of the product in some way that would affect the performance of your machine? A product with a ball or lead screw drive is often limited to stroke lengths of less than 2 meters, with some products accommodating strokes up to 4 meters. At these stroke lengths, speed is often limited due to screw ‘whip,’ so the product that achieves a particular speed at one stroke length often won’t achieve that speed at a longer one. Belt drives can achieve very long stroke lengths and perform much the same regardless of the stroke length, but they lack the precision of a screw-driven product. Linear motor-driven products offer performance that scales very well with stroke increases, while linear motors do not encounter speed limitations at longer strokes and will offer the same repeatability over full stroke.

Scalable Performance

Does the actuator you’re investigating offer multiple frame sizes or widths to select from? Having a number of different sizes to select from is beneficial for several reasons. To some extent, product price is proportional to size. If your application is too big for one product, you can find yourself jumping to a product that’s ‘overkill’ for the requirements. Having a family of products to select from allows you to cost-optimize the project. In addition, many multi-axis applications require different loading for each axis. Assuming you don’t want to overpay for an axis to maintain a uniform look and feel throughout the machine, selecting from a manufacturer’s family of actuators is typically the best way to maintain consistency.

Drive Train Options

Having multiple drive train choices in the same product is something that is often overlooked, but having screw or belt options within a given product can prove extremely useful to a machine designer. Within the same form factor, you can tailor the drive train to your need, be that the thrust density that you would get from a screw drive or the speed of a belt drive; the ability to choose either one without creating serious rework to the machine’s layout is a big advantage.

Modularity

Electromechanical actuators are almost never designed into a machine without being connected to other actuators or other mechanical devices. Being able to combine linear actuators into XY, XZ, or XYZ assemblies quickly and effortlessly is critical to machine builders. Most modern motion components are designed to be bolted together like motion building blocks, without the use of transition plates for XY systems. However, to maintain stability, plates are often unavoidable for the Z or vertical axes.

Performance

A bigger package size doesn’t always mean better performance; highly compact actuators or stages leave more space for machine designers to design in end effectors and tooling. As a result, factors like thrust or rated load per height-by-width become important metrics to evaluate when comparing electromechanical solutions for a given application. Optimizing extrusion profiles, bearing technology, and drive trains is not trivial to balance, especially when cost is critical.

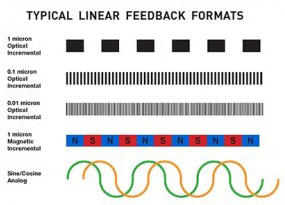

Selectable Resolutions and Encoder Types

High resolution encoders can be quite costly. Obviously, having a variety of resolution and encoder options to choose from always preferable to no choices. In order to maintain good servo control, an actuator should have 5 to 10 times more resolution available than the repeatability of motion required. The ability to vary the resolution is also important; some modern encoder products can be varied through a relatively simple hardware change. Another way to vary resolution is to use analog feedback devices and compatible servo drives. In using analog feedback signatures (usually 1Vp-p), two analog signals are passed from the encoder to the drive 90° out of phase with one another. Equivalent encoder resolution is established within the drive, and is dependent on the pitch of the linear scale and the resolution of the drive’s analog input.

In addition to flexible resolution, flexible encoder technologies are a major benefit. Optical encoders using glass scales have long been a popular choice, but other technologies now provide competitive resolutions and costs. In applications that don’t require exceptional precision, magnetic encoder technology is a very cost-effective alternative, and applications that do require high precision but not high stroke capacitive encoders allow for very high resolutions. Inductive encoders are a popular choice for applications directly exposed to heavy contamination, like coolant from a machine tool.

Applications that require constant positional information, regardless of an axis being homed, will require an absolute feedback source. Most of these encoder protocols had been designed with propriety signals embedded, which meant a designer had to use a limited list of manufacturers based upon the signal. Recently, open standard protocols like BiSS-C have become available, allowing designers to use any number of manufacturers’ drives or controls.

Digital Design

“Digital design” refers to more than just 3D CAD models of a product; it also means the ability to model the product’s performance in the digital space. Multi-physics design packages allow characterizing and designing products digitally before the first piece of metal is machined. Today’s cutting-edge Finite Element Analysis software allows designers to understand the thermal or magnetic variations within the product as well as deflection characteristics. Although no simulation can provide absolute certainty about how a design will perform (because a simulation can only be as good as the algorithms and assumptions that go into it), modern machine designers are increasingly reliant on digital design techniques to expedite the development of a machine.

Metrology Data

Virtually all modern electromechanical actuator suppliers characterize their precision products, which ensures that the product shipped meets (or exceeds) the published specifications. In the past, this data was captured using less precise and less reproducible methods like writing down readings from a dial indicator. Today’s metrology data is captured digitally, using more optical, non-contact methods like laser interferometry, which offers much higher resolution and much more repeatable data.

This test data can be used to characterize ball screw backlash, and can be used to improve overall system accuracy for high precision applications by electronically compensating for stage inaccuracies. For applications with very specific needs, other tests can be performed to mirror the actual application characteristics. Clean room applications are a good example of this because several application characteristics (speed, acceleration, orientation, flow of air in the chamber) can greatly change the performance of the product. Working with a design partner that can understand the mission-critical aspects of your application (and test to them) can be an invaluable advantage to a machine builder.

Integrated and Optimized Complementary Products

When selecting an actuator, motor, drive or controller, most modern component manufacturers offer standard cable configurations to simplify connectorization and configuration. With some of the latest drive and encoder technologies, data stored down at the motor allows the drive to recognize motor parameters automatically. The drive is simply connected, powered up, then automatically fed the motor information from the encoder. After that, all that’s needed is a quick auto-tuning to adjust for the payload and the machine is ready for motion.

A machine builder’s livelihood very much depends upon the ability to design, build, and ship a machine as quickly as possible. Machine customers who were once content to wait several months for design, configuration and delivery of their equipment now expect it in weeks.

They key to the machine building success in the 21st century is selecting the right product from a manufacturer that understands the day-to-day design hurdles and has built systems in place that allow for the rapid development your machine.

This article originally appeared on EDriveOnline, April 4, 2016.