![]() Originally Posted on March 23, 2016 by larieubtler on NSK AMERICAS BLOG

Originally Posted on March 23, 2016 by larieubtler on NSK AMERICAS BLOG

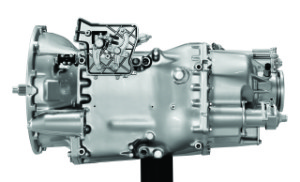

An automotive supplier, who produces aluminum transmission housings, was experiencing issues with its transmission leak testing equipment. The facility was experiencing a 20% failure rate once its transmission housing reached the test phase.

When a failure occurred, a new test had to be administered leading

When a failure occurred, a new test had to be administered leading

to reduced throughput.

It was determined that the bushing system used to transport the transmission housing into the test area was the leading cause of the issue. The bushing system didn’t deliver precise movement or protect transmission housing against contamination.

NSK proposed that the installation of NH Series Stainless Steel Linear Guides with K1™ Lubrication Units be used in replacement of the bushing system.

NH Series Linear Guides are known for offering maximum precision, high load ratings and smooth linear motion. This product line is used for a wide variety of applications and has proven success in medical technology, semiconductor, machine tool and automotive industries.

Adding K1™ Lubrication Units provides long-term maintenance-free operation by allowing fresh, continuous oil to flow onto rail during operation. This innovative solution is ideal for environments where grease replenishment is undesirable or in areas where grease is easily washed away.

Once NH Series Stainless Steel Linear Guides with K1™ were installed in the facility, the failure rate was reduced to 6% which significantly improved throughput and decreased cost per piece produced.

Once NH Series Stainless Steel Linear Guides with K1™ were installed in the facility, the failure rate was reduced to 6% which significantly improved throughput and decreased cost per piece produced.

Cost Savings Breakdown:

Bushing Method

Production Cost: 810 parts per month: $75,632 x 12 months = $907,584

NSK Solution

Production Cost: 940 parts per month: $64,273 x 12 months = $771,276

Total Annual Savings

Total Cost of Bushing Method minus Total Cost of NSK Solution

= $136,308 total cost savings!

If you’d like to receive more information about NSK linear motion products, please contact RSA.

Story originally posted on NSK Americas web site.