Originally posted by Parker Electromechanical Team on November 3, 2016

Originally posted by Parker Electromechanical Team on November 3, 2016

For challenging automation motion control applications such as packaging machines and rotary tables, some servo drives need to be housed outside the electrical cabinet. Although the traditional style of keeping them inside the cabinet maintains the electrical components and wiring in a safe environment, enclosing them in cabinets can be expensive, labor intensive and space-consuming.

With the growing number of axes used in automated machinery, the decentralized servo drive solution confidently delivers many advantages. Here are just three.

With the growing number of axes used in automated machinery, the decentralized servo drive solution confidently delivers many advantages. Here are just three.

1. Smaller cabinets with less wiring

One obvious advantage of mounting servo drives outside the cabinet is the control cabinet will be significantly smaller.  A decentralized approach to motion control functionality means huge amounts of wiring can be done away with by ‘daisy-chaining’ all of the drives in series with a hybrid cable to transfer the power, control and communications signalling. In an application with four motors, where the distance between the cabinet and the machine is 10 meters, a standard solution would require eight different cables to connect the drives to the motor, totaling 100 meters of cabling. With a decentralized solution, this can be reduced to five cables with a total length of not more than one meter.

A decentralized approach to motion control functionality means huge amounts of wiring can be done away with by ‘daisy-chaining’ all of the drives in series with a hybrid cable to transfer the power, control and communications signalling. In an application with four motors, where the distance between the cabinet and the machine is 10 meters, a standard solution would require eight different cables to connect the drives to the motor, totaling 100 meters of cabling. With a decentralized solution, this can be reduced to five cables with a total length of not more than one meter.

2. Easier and more energy efficient design

Machine design also becomes easier because of the modularity of the decentralized servo drives. Extra axes can be added to the design simply by duplicating the schematic drawings from other axes. This easier design not only reduces engineering time and costs but also simplifies the assembly process and accelerates time to market. An additional benefit is that the energy-efficient decentralized servo drives work on a common DC bus power supply, which means the system can absorb and resupply much of the braking energy to other servo drives units rather than dissipating it in the form of heat via external resistors. As a result, resistors can be removed completely in certain applications, while in others smaller resistors are sufficient.

Machine design also becomes easier because of the modularity of the decentralized servo drives. Extra axes can be added to the design simply by duplicating the schematic drawings from other axes. This easier design not only reduces engineering time and costs but also simplifies the assembly process and accelerates time to market. An additional benefit is that the energy-efficient decentralized servo drives work on a common DC bus power supply, which means the system can absorb and resupply much of the braking energy to other servo drives units rather than dissipating it in the form of heat via external resistors. As a result, resistors can be removed completely in certain applications, while in others smaller resistors are sufficient.

3. Great protection against dust and moisture

Servo drives specially designed for outside-the-cabinet applications, such as our Servonet DC decentralized double-axis servo drives, offer a robust IP67 housing tailor-made for rugged and harsh environments.

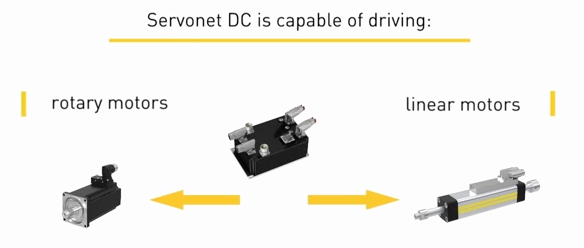

With the Servonet DC, all wiring changes are made on the machine via plug and socket Faston connectors rather than in the cabinet. The complete system is complemented by an extensive series of servo motors, both rotary and linear, and finally a power supply and suitable interface module, which are the only parts that remains inside the cabinet.