There is no “one size fits all” drive train linear actuator technology for every application. In reality, the selection depends entirely on what is most critical to a specific application. While choosing to use a lead screw seems straight forward, choosing between ball and roller screws can be daunting. You can simplify the selection process by approaching the application systematically and applying an actuator performance calculator.

There is no “one size fits all” drive train linear actuator technology for every application. In reality, the selection depends entirely on what is most critical to a specific application. While choosing to use a lead screw seems straight forward, choosing between ball and roller screws can be daunting. You can simplify the selection process by approaching the application systematically and applying an actuator performance calculator.

To choose the proper technology, consider quantifying metrics rather than relying upon product labeling and initial perception.

An application example

An application example

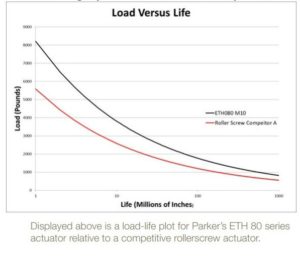

This chart represents an application requiring 1000 lbs of continuous thrust, over a 10-inch stroke, moving at 12 in/sec at 100% duty cycle. In this application, the objective is to maximize the life of a particular actuator. Given the high duty cycle of this application, this analysis will focus on electric cylinder screw options of similar pitch and packaging.

This is an excerpt from the Parker EM&D blog. To read the full article, click here