An OEM customer was looking for a cost-effective solution to control a Single-Sheet Hand-Fed Laminator. The project included some general digital & analog I/O Machine Control (solenoid valves for engaging rollers, analog and digital VFD control to move the paper through the laminator, and etc…), but not too much; all a good fit for the Samba series.

But there was another challenge that needed to be addressed: At the outlet of the laminator, a rotary-knife was to be driven in synchronization with the line speed of the paper, to perform a separating cut for each sheet that left the laminator. The customer had pursued a stepping motor solution in the past, but this restricted the machine to a single speed, which greatly devalued its functionality.

Enter Parker’s IPA Servo Drive/Controller paired with, of course, an adequately sized servo motor. The IPA is able to receive a reference external encoder for CAMMING and Gearing operations, and do High-Speed Interrupts to capture the encoder’s position within microseconds of receiving a signal from the machine’s sheet detector.

Enter Parker’s IPA Servo Drive/Controller paired with, of course, an adequately sized servo motor. The IPA is able to receive a reference external encoder for CAMMING and Gearing operations, and do High-Speed Interrupts to capture the encoder’s position within microseconds of receiving a signal from the machine’s sheet detector.

Using the IPA’s programming language, AcroBASIC (Parker’s software is also free. Love it.), I was able to program a sheet-position capture buffer that can track up to 5 sheet signals, and have user-adjustable distances from their captured positions to enact machine functions that are resultantly line-speed invariable.

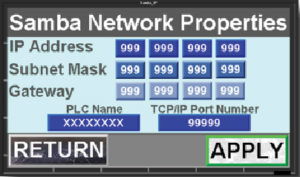

In Visilogic, I was able to construct a subroutine containing every line of ladder logic needed to connect to the IPA, exchanging commands from the user on the HMI, and receiving the servo status. If I ever need to add a servo axis to a machine with Unitronics on it; I’ll copy, paste, and adapt in no time.

.